A new generation of high-speed inkjet press from the market leader rivals offset and puts you in control of your business.

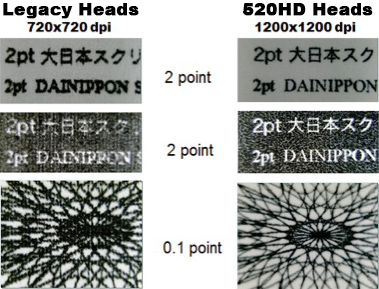

What sets the Truepress Jet520HD systems apart is their unique printhead technology. The presses are able to place 2-picoliter droplets – the world’s smallest level – exactly where the dots are required on paper as it moves through a high-speed transfer system. Combined with the maximum true resolution of 1,200 dpi, the Truepress Jet520HD printers clearly image details smaller than 0.10 of a point. The result is a sharp, eye-catching finish with no ink spread or jaggies.

An enhanced version of the Equios professional workflow system allows for increased production benefits, not only automating job and color management but also providing in-RIP imposition, JDF communication and PDF/VT support. Even with high-volume variable data and high-resolution images, print quality can be maintained without compromising all-important productivity.

SCREEN will be introducing the first high-speed roll-fed monochrome press in late 2020. The Truepress Jet520HD mono will be equipped with SCREEN GA's unique Truepress ink SC range, which has already established an impressive track record with other Truepress Jet520HD models. These inks give the press the ability to print directly onto offset coated papers.

New wide-gamut inks for direct inkjet printing on offset coated paper for the Truepress Jet520HD!

SC Inks feature breakthrough absorption technology eliminating any preprocessing or additional primer coatings that are typically required to print to standard offset coated papers. Printing directly to the paper saves time and cost and preserves the paper surface texture to open up a range of new possibilities and new markets for inkjet printing including commercial print, catalogues, magazines and high end books.

With the introduction of Truepress SC Inks for use with SCREEN’s TPJ520HD, SCREEN has built a compelling argument that its new offering will bring high-speed digital printing into high-quality areas that have been relatively untouched so far by production digital printing methods. Download White Paper »

JetInspection, SCREEN’s dedicated inspection system, performs comprehensive, real-time inspection of variable images across all pages. Controlled directly from the operation panel, JetInspection uses a camera to capture barcodes and optical character recognition fonts and output the inspection results after decoding. It also checks for missing dots, color variations and improperly output text.

Download the Image Test Lab’s Assessment Report of the Truepress Jet 520HD’s print stability and consistency compared to commercial color offset.

EQUIOS PrintSimulator is a powerful tool designed to detect any errors embedded in a PDF. With the PrintSimulator, multiple PDFs are analyzed simultaneously at high speeds. PrintSimulator assists in achieving high levels of productivity, stability and accuracy in print operations.

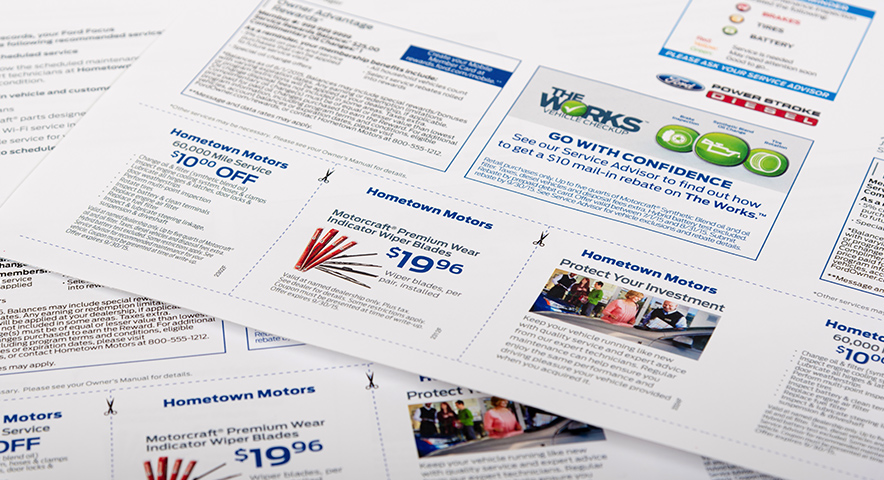

SCREEN high-speed inkjet presses are changing the look and feel of monthly statements, invoices, policies and other documents. Attention-grabbing color and targeted messages combine with fast throughput to add value to every customer communication.

When it comes to reliable production, faithful color and fast turnarounds for a variety of high-volume commercial printing applications, SCREEN Truepress Jet520 series inkjet web presses satisfy all your customers’ demands. Flexible system configurations and versatile options allow you to build the production solution you need.

SCREEN technology creates new opportunities to use continuous-feed inkjet for high-end publications and digital book printing that were previously impossible. SCREEN inkjet web presses leverage the speed advantages of digital technology while providing opportunities for variable data, full color and different text stocks.

Time to market is everything in the print-and-mail world. For time-sensitive, mission-critical communications that get results for your clients, look no further than SCREEN high-speed inkjet.

SCREEN Graphic Solutions Co., Ltd., also referred to as SCREEN GA, announces that it will take part in Horizon Smart Factory 2024, to be held by Horizon Inc. at its Biwako Plant located at 1600 Asahi, Shinasahi-cho, Takashima, Shiga, Japan, on October 2 to October 4, 2024, from 10:00 a.m. to 5:00 p.m. daily.

SCREEN Americas announces the installation of the Truepress JET 520HD+ at Allegra Marketing•Print•Mail, a corporate-owned franchise located in Plymouth, Michigan.

CEO Fadi Lahlouh of Lahlouh sat down at PRINTING United Expo to share his secrets for successful direct mail campaigns. The executive at the family-owned operation turned to SCREEN Americas for advice on how to strategically market direct mail applications and says that having access to upper management at SCREEN is the key to a great partnership.

In this exclusive interview with Dave Johannes of Moore, the executive vice president of strategic initiatives takes a deep dive into his company’s approach to personalization and explains how SCREEN technology has afforded Moore the ability to incorporate advanced variable content into direct mail projects.

Standard functions and configuration

Charged options

| Model | Truepress Jet520HD | Truepress Jet520HD+ | Truepress Jet520HD AD | |

|---|---|---|---|---|

| Print speed (Standard uncoated, IJ treated uncoated papers) | 50 m/m (1,200 x 1,200 dpi) | |||

| 75 m/m (1,200 x 600 dpi) | ||||

| 100 m/m (1,200 x 600 dpi) | ||||

| 120 m/m (600 x 600 dpi) | ||||

| 150 m/m (600 x 600 dpi) | * | * | * | |

| Print speed (IJ treated coated papers) | 50 m/m (1,200 x 1,200 dpi) | |||

| 75 m/m (1,200 x 600 dpi) | ||||

| 100 m/m (1,200 x 600 dpi) | ||||

| 120 m/m (600 x 600 dpi) | ||||

| 150 m/m (600 x 600 dpi) | * | |||

| Print speed (Standard coated papers with no IJ treatment) | 50 m/m (1,200 x 1,200 dpi) | |||

| 75 m/m (1,200 x 600 dpi) | ||||

| 100 m/m (1,200 x 600 dpi) | ||||

| 120 m/m (600 x 600 dpi) | ||||

| 150 m/m (600 x 600 dpi) | * | |||

| Drying system | Air heating + heat drum | |||

| Air heating + heat drum + additional dryer (NIR) | ||||

| Advanced dryer unit | ||||

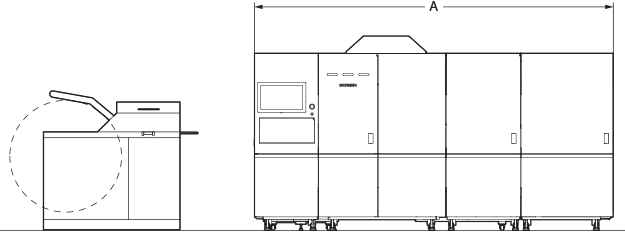

| Dimensions (printer section only) | 4,070 x 2,370 x 2,200 mm (160.3” x 93.4” x 86.7”) | 4,070 x 2,370 x 2,400 mm (160.3” x 93.4” x 94.5”) | 4,070 x 2,370 x 2,360 mm (160.3” x 93.4” x 93.0”) | |

| Weight | Approx. 4,050 kg (8,910 lb) | Approx. 4,120 kg (9,064 lb) | Approx. 4,470 kg (9,834 lb) | |

| Power requirements | Printer Controller: Three phase 200 to 240 V, 30 A / 380 to 415 V, 20 A Heater: Three phase 200 to 240 V, 110 A / 380 to 415 V, 55 A Controller PC: Single phase 100 to 240 V, 2 A | Printer Controller: Three phase 200 to 240 V, 30 A / 380 to 415 V, 20 A Heater: Three phase 200 to 240 V, 110 A / 380 to 415 V, 55 A Controller PC: Single phase 100 to 240 V, 2 A Additional dryer (NIR): Three phase 180 to 220 V, 110 A / 380 to 480 V, 50 A (A separate 400 V step-up transformer is required when using 200 V facilities) | Printer Heater & controller: Three phase 200 to 240 V, 120 A / 380 to 415 V, 75 A Heater: Three phase 200 to 240 V, 130 A / 380 to 415 V, 80 A Controller PC: Single phase 100 to 240 V, 2 A | |

* The 150 m/m printing speed can be used with paper that is between 64-157 gsm

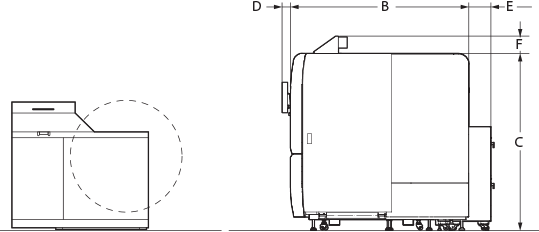

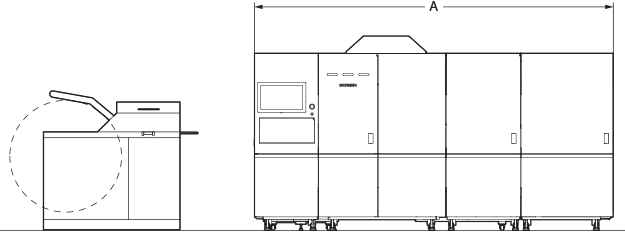

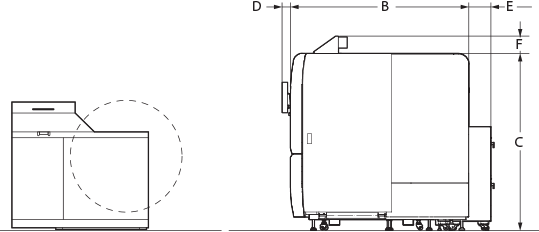

| A | B | C | D | E | F | |

|---|---|---|---|---|---|---|

| Jet520HD | 4,070mm (160.3”) | 2,025mm (79.8”) | 2,005mm (79”) | 93mm (3.7”) | 250mm (9.9”) | 195mm (7.7”) |

| Jet520HD+ | 4,070mm (160.3”) | 2,025mm (79.8”) | 2,005mm (79”) | 93mm (3.7”) | 250mm (9.9”) | 398mm (15.7”) |

| Jet520HD AD | 4,289.5mm (168.9”) | 2,025mm (79.8”) | 2,005mm (79”) | 93mm (3.7”) | 250mm (9.9”) | 351mm (13.9”) |

| Printing system | Inkjet, Piezo single-pass DOD |

|---|---|

| Controller | EQUIOS: PS, PDF, PDF/VT (standard) IPDS Controller: AFP/IPDS (optional) |

| Inks | Truepress ink SC for Truepress Jet520HD CMYK (standard) |

| Resolution | Max. 1,200 x 1,200 dpi |

| Printing speed | Max. 150 m (492')/min. (with option)* |

| Printing width | 150 to 508 mm (6” to 20”) |

| Media width | 165 to 520 mm (6.5” to 20.4”) |

| Media thickness | 40 to 250 gsm (up to 157 gsm for the speed of 150 m/min.)* |

| Operating environment | Temperature: 18 to 24°C (64.4 to 75.2°F) (no sudden temperature changes) Humidity: 40 to 60% (no condensation) |

*Under SCREEN's conditions

| Built-in Camera System | Nozzle Check & Real Time Monitor | OCR & Decode | All Image Storage | Full Variable Inspection | |

|---|---|---|---|---|---|

| Monitoring Solution | |||||

| Evidence Solution CSV Evidence | |||||

| Evidence Solution Image Evidence | |||||

| Evidence Solution CSV & Image Evidence | |||||

| Full Variable Inspection Solution Full Variable Inspection + CSV | |||||

| Full Variable Inspection Solution Full Variable Inspection + CSV & Image |

| Hardware Option | Operating Environment | |

|---|---|---|

| Monitoring Solution | Not required* | Conforms to operating environment of main press and EQUIOS system |

| Evidence Solution | 1 dedicated personal computer (HW OP 1st unit) | Conforms to operating environment of main press and EQUIOS system, additional hardware is described below |

| Full Variable Inspection Solution | 2 dedicated personal computers (HW OP 1st, 2nd units) | Conforms to operating environment of main press and EQUIOS system, additional hardware is described below |

*It may be necessary to purchase a camera unit separately if one is not installed in the Truepress Jet520HD printer.

| Power requirements | Input: 100 to 240 V AC Electricity consumption: 240 W |

| PC dimensions (W x D x H) | 430.4 x 444.4 x 177.4 mm (17.0" x 17.5" x 7.0") (4U) |

| Weight | 16 kg (35.2 lb) to 23 kg (50.6 lb) |

| Installation | Horizontal installation in EQUIOS rack (rails for rack provided) The monitor, keyboard and hub share items in the EQUIOS rack. |